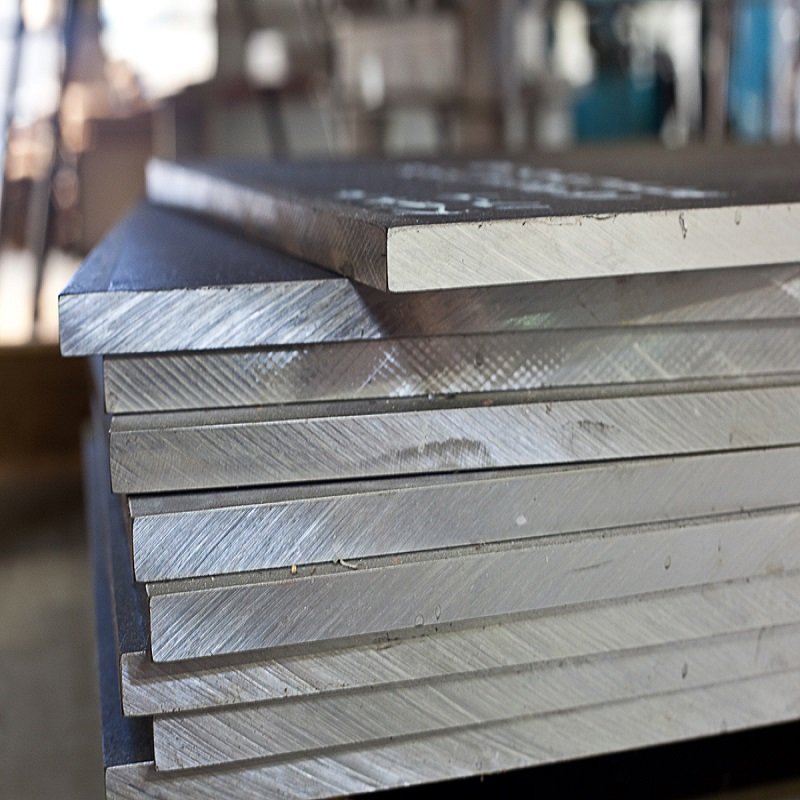

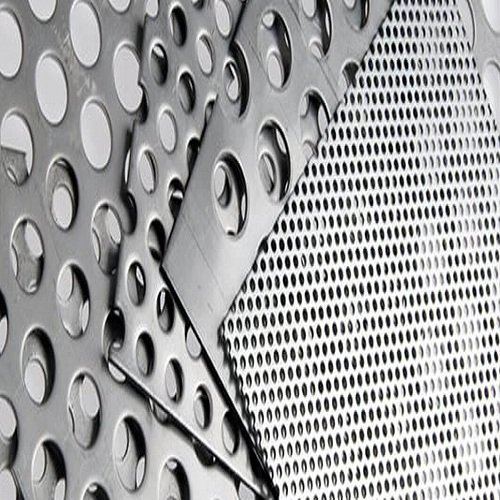

Unisteel and Engineering offer a wide scope of that is secured from surely understood merchants of the world. These adjust to the global quality measures and are known for upgraded toughness and protection from consumption. Accessible in different evaluations, our range can likewise be redone according to the particulars of our customers. sailma 410/410HI plate investors and providers, conveying to the entire of the world. sailma 410/410HI plate provided by us are acknowledged by customers in different circles of the ventures running from fundamental businesses, for example, Sugar, Paper, Textile, Dairy, Engineering to increasingly complex, for example, Oil & Gas, Petrochemical, Chemical & Fertilizers, Power Generation and Nuclear Industries. we are ISO 9001:2008 authorize and supplies sailma 410/410HI plate to globally affirmed quality norms for applications. sailma 410/410HI plate have superb quality to completely fulfill client and prerequisites sailma 410/410HI plate we offer amazing, lower cost yet the best administration. Accordingly to that our fare account today is in different nations like Egypt, South America Saudi arabia, Thailand,Kuwait,Kazakhstan, Qatar, Oman, Yemen, UAE, Iran, Turkey, Greece, Singapore, Indonesia, Vietnam, South Africa,,Brazil, India, Australia.

We offer high evaluation sailma 410/410HI plate at reasonable cost. These sailma 410/410HI plate are produced utilizing best grade crude material accessible to guarantee universal quality. These sailma 410/410HI howdy plate are accessible fit as a fiddle size and thickness as per the necessities of our client. Inferable from very experienced gathering of qualified proficient and utilization of most recent innovation hardware, Unisteel and Engineering. have provided astounding sailma 410/410HI hello there plate and profiles to clients all through the around the world. Just as being accessible from stock all sailma 410/410HI hello there plate can be sliced to size and shape as per your creation and structure necessities and all work is administered by our autonomously certify and consistently evaluated quality frameworks. Our are sourced from the most astounding quality steel producers on the planet and, similar to every one of our providers, these makers have been considered and evaluated by our obtainment group.