We manufacture, export & supply EN 10204 Duplex Steel S32550 Welded Pipes to spheres of industries ranging from basic industries such as Sugar, Paper, Textile, and Engineering to more complex such as Oil & Gas, Petrochemical, Chemical & Fertilizers, Power Generation and Nuclear Industries. Super Duplex Stainless steels, which combine high strength and excellent corrosion resistance in many environments, have found applications in chemical and process industries. Pulp mills, offshore systems, flue gas desulphurization units. The localized corrosion resistance of Super-Duplex Steels is close to what is achieved with 6% Mo Super-Austenitic grades.

At our company, we pack UNS S32550 welded pipes carefully to ensure they reach our consumers in perfect shape. High-quality materials like wooden crates and cardboard boxes are employed to secure the pipes from potential harm while they are being sent. Every single pipe is encased with protective material and tightly bound to protect against any activity throughout shipment. The packages are additionally clearly marked, so the detection and shipping are convenient. When ordering from us, you can be confident that your DIN 1.4501 pipes will get to you in great condition.

Table of Contents :

- About OF Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- SPECIFICATIONS OF Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Type OF Super Duplex Steel F61 - UNS S32550 Pipe / Tube

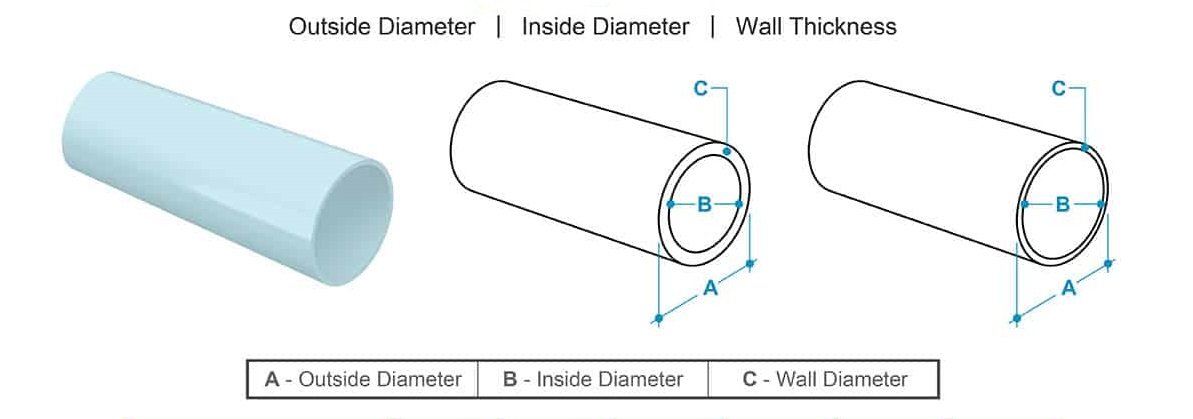

- Dimensions of Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Size OF Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- AVAILABLE STOCK OF Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Equivalent Grades of Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Chemical Composition OF Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Mechanical Properties OF Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Price list of Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Testing of Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Packing of Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- Application of Super Duplex Steel F61 - UNS S32550 Pipe / Tube

- GLOBAL NETWORK OF DUPLEX STEEL & ENGINEERING Co.(P) Ltd.