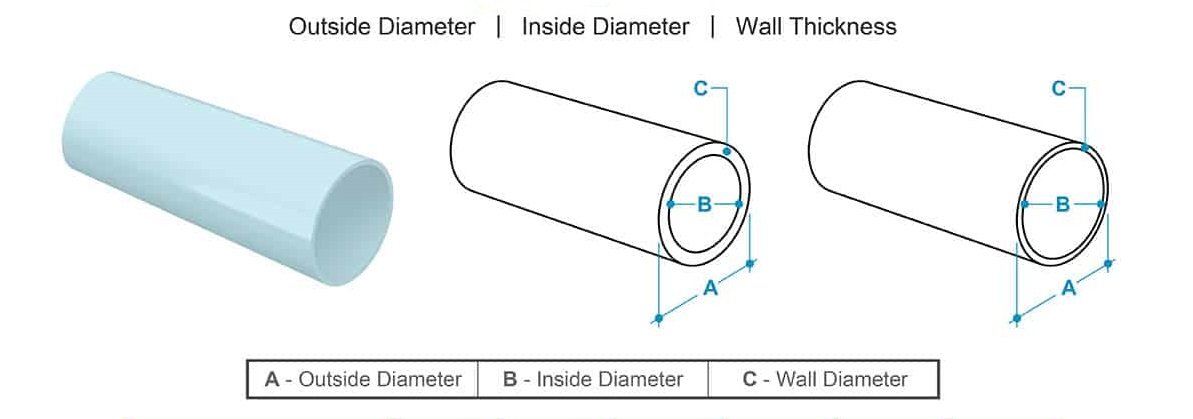

We are affianced in providing a wide gamut of Inconel 718 pipe to the clients. The provided pipes are efficiently manufactured using the superior quality nickel alloy with the aid of pioneering methodology. Further, These ASTM B670 Inconel 718 Seamless Pipe are used for transferring liquid and other fluids to several industries. We have a team of experienced professionals with years of experience in manufacturing. Inconel 718 Pipes and other nickel-based alloys are suitable for cost-effective development of oil and gas pumps, valves and process controlling equipment. Inconel 718 Sch 40 pipe is a superalloy made from nickel-chromium designed for a wide range of harsh corrosive conditions and crevices. This nickel alloy has exceptionally high efficiency, tensile and rupture at high temperatures. It used at 1200 ° F from cryogens to long term service.

Key CHARACTERISTIC :-

- Corrosion resistance

- Resistance to oxidation and sulfidation

- Surface finish

- Magnetic properties

- Ductility

- Suitability for intended fabrication techniques