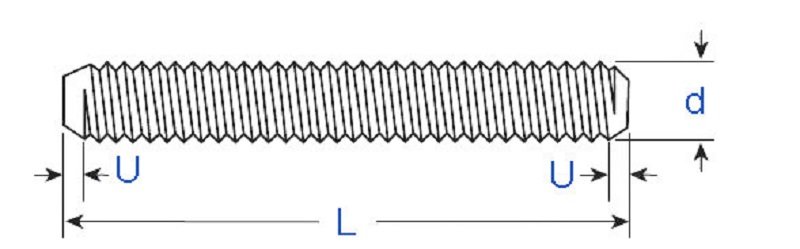

DUPLEX STEEL & ENGINEERING are trustworthy organization among the others, involved in to manufacturer, supplier and exporter of high quality Ldx S32101 Fasteners, that are being designed as per the national and international standard quality of raw materials and thus making sure of their durability and high quality. We manufacture high standard quality of these Lean DuplexSteel 2101 Anchore Screw and are offered in standard sizes that ranges from M10 TO M100 and as well in customized length. The structure of Duplex Stainless Steel UNS S32101 Panel Screw & Machine Screw Fasteners consists of austenite pools surrounded by a continuous ferrite phase.

We export Duplex Steel S32101 Concrete screw / Fasteners which is the most widely used duplex stainless steel grade, which is characterized by high yield strength. Lean duplex stainless steels possess high strength coupled with corrosion resistance as compared to Austenitic grades like 316L. This grade has stable cost owing to low nickel and molybdenum contents. This can easily substitute standard austenitic grades like 304, 304L and even 316L in most environments.