Super Duplex UNS S32760 Round Bar has many properties as well as characteristics because of the elements present in the chemical composition. Because of these properties as well as characteristics these Super Duplex UNS S32760 Round Bar are used in a large number of industrial applications.

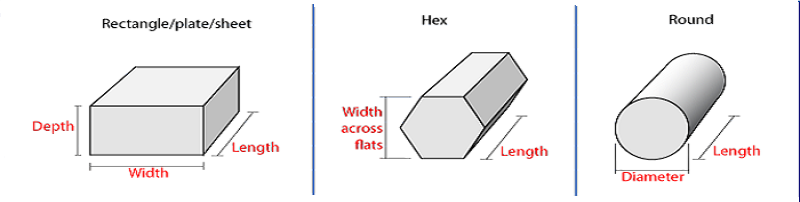

These Super Duplex UNS S32760 Round Bar could be available in a range of shapes, sizes as well as diameters depending upon the needs and requirements of the applications as well as the specifications provided by the client. These Super Duplex UNS S32760 Round Bar have the property of being resistant to localized corrosion. It is also resistant towards stress corrosion cracking. They also have the property of great mechanical strength. While manufacturing these Super Duplex UNS S32760 Round Bar the necessary rules as well as regulations are taken into consideration so that these satisfy the demands of the client.