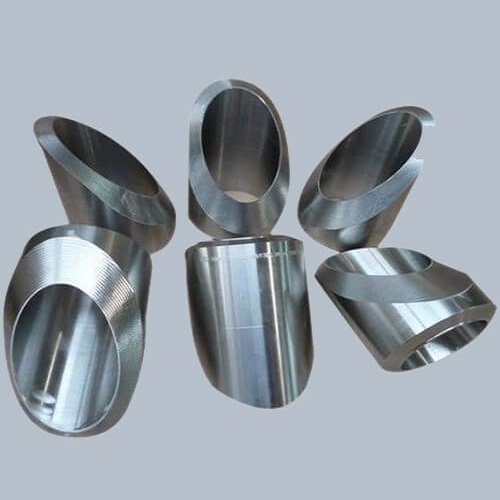

We are manufacturer of Alloy Steel WP 5 Butt weld Pipe Fittings that are made available in varied sizes. We are affianced in providing a wide gamut of Alloy Steel F5 Butt weld Pipe Fittings to the clients. DUPLEX STEEL & ENGINEERING one of the leading manufacturer, exporter and supplier of Alloy Steel ASTM A234 WP5 Butt weld Pipe Fittings in India.

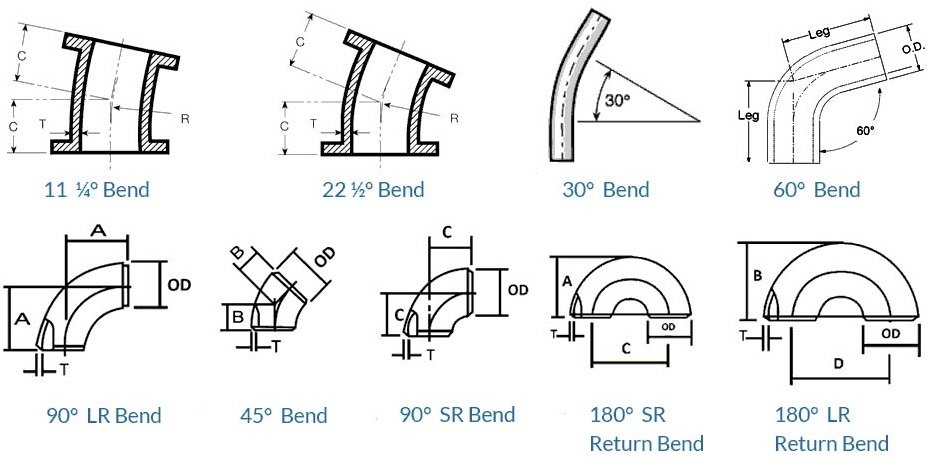

Alloy Steel F5 Seamless Fitting and Alloy WP5 Welded Fitting grades of Alloy WP5 fitting exhibit good machinability and have excellent weld-ability characteristics with or without the addition of filler metals. These Alloy Steel F5 Butt weld Fitting are available in different form 90 Elbow, 45 Elbow, Long Radius Elbow, Short Radius Elbow, Bends 1.5d, 3d, 5d, 10d, 180 Deg Bend, U bend, Concentric Reducer, Eccentric Reducer, Cross, Short Stub End, Long stub end, End Cap, Dish Cap, Equal Tee, Unequal Tee, Lateral Tee, etc.