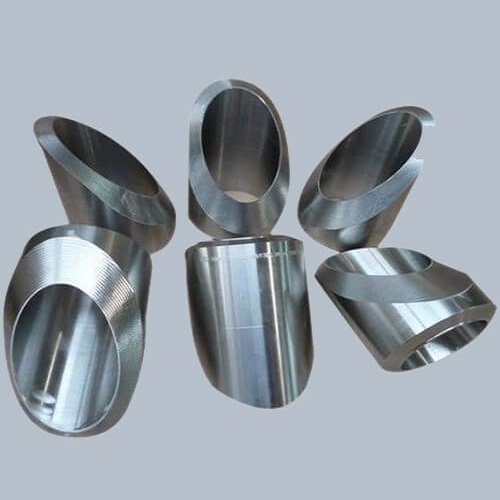

DUPLEX STEEL & ENGINEERING is one of the leading manufacturer, supplier and exporter a wide assortment of Inconel 718 Socket weld Forged Fittings. Our Alloy 718 Socket weld Forged Fittings are produce with utmost precision, ensuring that our range of products comply with international quality parameters. Our Inconel 718 Socket weld Fittings are made in compliance with the international quality standards and by making use of the best quality inconel alloy. We focus in manufacturing custom shape and special size socket weld fittings for our clients.

Our offer Inconel 718 Socket weld Cross Forged Fittings is available in various sizes and thicknesses to meet all customer centric requirements, Alloy 718 Socket weld Forged Coupling are suitable for usage in aqueous and low-temperature environments. The austenitic structure of Inconel 718 Forged Socket weld Union also results in a change in the physical properties of the steel. Inconel 718 Socket weld Forged Fittings and Alloy 718 Forged Fittings highly demanded in various industries & industries application Chemical Plants, Oil Refineries, Fertilizers Plants, Sugar Mills, Cement industries Petrochemicals Plants, Power Industries Industrial Machineries, Textile Machineries and Pharmaceuticals Plants etc.