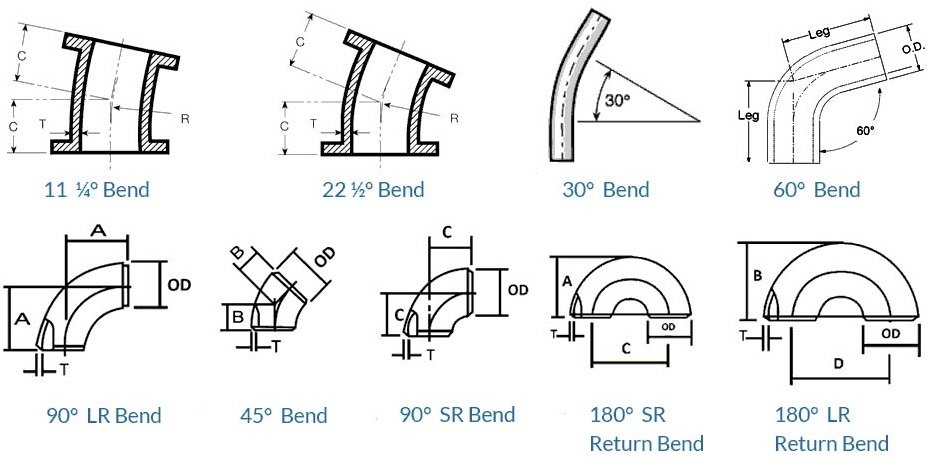

DUPLEX STEEL & ENGINEERING is leading organization involved in manufacturing & exporting of Stainless Steel 310/310S Socket Weld Fittings. These UNS S31000 | S31008 Socket Weld Fittings are available in various forms and sizes and is assured to be provided to clients at high quality. Our offered SS 310/310S Socket Weld Couplings are the building blocks with appropriate standard and help bear a lot of pressure, thus making it durable over the years. Our Stainless Steel 310 Socket weld Fittings | UNS S31000 is an austenitic chromium-nickel steel with high strength and excellent corrosion resistance. We are produceer of wide range of Stainless Steel 310S Socket Weld Elbow Fittings is widely used in moderately carburizing atmospheres such as encountered in petrochemical environments. The electric arc furnace (EAF) method of UNS S31000 | SS 310 Forged Socket Weld Cap production can use exclusively recycled steel.

Our SS 310 Socketweld Tee and SS 310S Socket Weld Lateral Tee Fittings is suggested for applications where sensitisation, and subsequent corrosion by high temperature gases or condensates during shutdown may pose a problem. Grade 310 (UNS S31000) and its various subgrades combine excellent high temperature properties with good ductility and weldability. Grade 310H (UNS 531009) has a carbon content restricted to exclude the lower end of the 310 range, so is the grade of choice for high temperature applications. Grade 310S (UNS S31008) is used when the application environment involves moist corrodents in a temperature range lower than that which is normally considered "high temperature" service. The lower carbon content of 310S does reduce its high temperature strength compared to 310H.

"Dual Certification"

310H and 310S are often produced in "Dual Certified" form - mainly in plate and pipe. These items have chemical and mechanical properties complying with both 310H and 310S specifications. Product complying with 310 only or dual certified 310 and 310S may have a carbon content below 0.04% which will not be acceptable for some high temperature applications.

Typical Applications

Furnace parts. Oil burner parts. Carburising boxes. Heat Treatment baskets and jigs. Heat exchangers. Welding filler wire and electrodes.