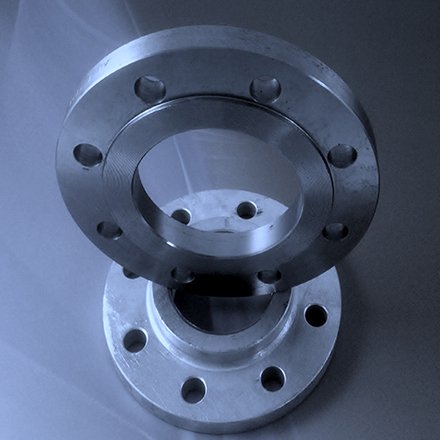

Duplex S31803 flanges are hardened alloy which are made from high superior quality raw material. These Duplex Steel S31803 flanges are commonly used for high temperature applications. These flanges are commonly used for connecting pipes, pumps and valves together. A flange is a circular ring which is normally installed at the end of the pipe. These flanges are generally bolted or welded which depends upon its applications. These flanges have a wide variety of types. Duplex is a strong grade which is made from a mixture of austenitic and ferrite microstructure. This grade is considered as the most strongest and ductile grade which provides extraordinary strength.

Duplex S31803 flanges can easily withstand temperature upto 300°C, which is why it is more preferable at high temperature applications. UNS S31803 flanges provide excellent resistance from corrosion, crevice corrosion and stress cracking. These flanges are extremely weldable and they also support pitting.

Chemical composition: The chemical composition of duplex S31803 flanges includes high amounts of chromium and nickel in its composition. Other than that the grade also includes a decent amount of iron, molybdenum, manganese, silicon, and phosphorus. All of these elements are added to provide stability and robustness to the grade.

Mechanical properties: The S31803 Duplex Steel flanges have high tensile and yield strength. The minimum tensile strength the grade has is approximately 620 Mpa whereas the minimum yield strength is 450 Mpa. It also has high rupture and creep strength. At Unisteel and Engineering co., we provide you with the best quality steel products at the most reasonable prices. We make sure that every product is conscientiously tested and certified by professionals.