Duplex is one of the strongest grades available in industries today. Duplex is considered as the most ductile and robust grade which is why it is used in the manufacturing of high temperature applications. Duplex has the ability of fighting sulphide stress corrosion. It has great durability which makes it last longer than other alloys. Duplex is available in many grades but, UNS S31803 is considered as the most recommended and preferable alloy for the commercial and industrial usage.

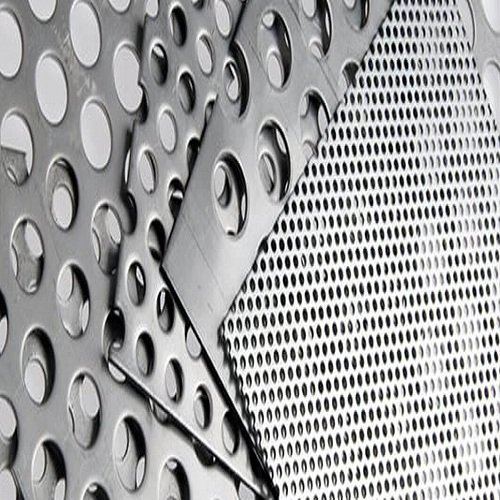

Duplex UNS S31803 coils are considered to be the most malleable and strong equipment for use in high temperatures. This grade is enhanced with great stability and strength. Unisteel and Engineering co is the most astonishing manufacturer, importer and supplier of duplex UNS S31803. We provide these grades in the form of sheets, plates, coils and other equipment. Duplex UNS S31803 sheets, plates and coils are well liked and highly demanded in construction and commercial industries. Sheets are popularly used in roofing industries, heat exchangers, and metallurgical industries whereas coils are used in switchgear industries.

Chemical composition: The chemical composition of Duplex UNS S31803 plates includes heavy elements like chromium, nickel, molybdenum etc. All of these elements are known for providing rigidness and sturdiness to the grade. This excellent combination provides extreme resistance from various chemical procedures.