Duplex is the most durable and ductile grade, which provides excellent features and characteristics. It is enriched with great strength and high resistance from various chemical and physical reactions. Duplex S31803 pipes has the most sturdy grade, commonly used for its significant characteristics. The duplex grade is made from various extraordinary elements, which are commonly combined to form a robust, malleable piece of metal. We at Unisteel and Engineering co. use high-quality raw materials. These pipes are widely used for transferring liquid, acids and other fluids from one place to another. These tubes and pipes are commonly used for industrial purposes, and these pipes or tubes are also used in basic household applications.

Chemical composition: The chemical composition of duplex S31803 tubes are made from a great combination of elements. It includes a decent amount of chromium, nickel and molybdenum. The grade also contains silicon, manganese and iron. The inclusion of all these elements provides stability and efficiency to the grade. The high amount of chromium provides excellent welding and pitting resistance.

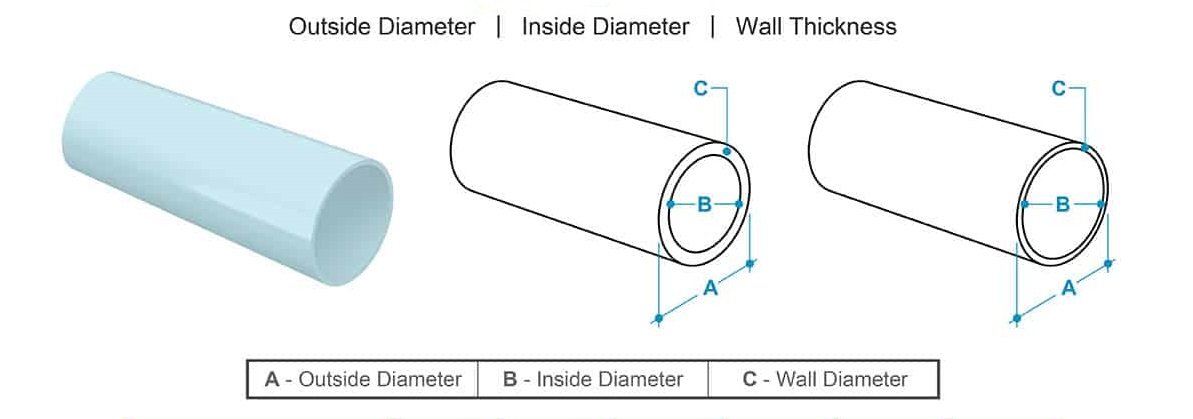

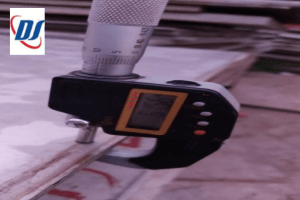

Mechanical and physical properties: Duplex S31803 pipes-tubes are enriched with high tensile and yield strength. It also has a high melting point, making it ideal for high-temperature applications. The grade also has high creep and rupture strength. At Unisteel and Engineering co., we provide you with the best quality steel products at the most reasonable prices. We make sure that every product is conscientiously tested and certified by professionals.