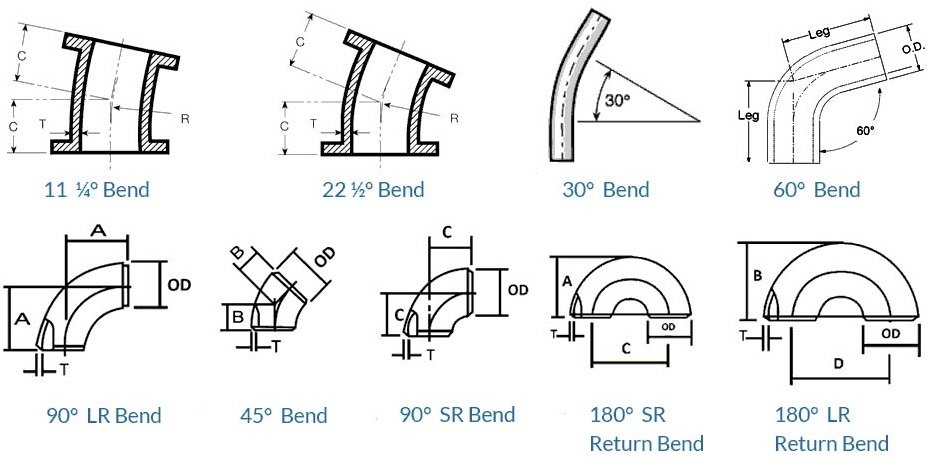

Our wide variety of SS 317 | UNS S31700 Socket Weld Lateral Tee fittings is are made up with industrial standards and are also made available by us in different finish specifications and usually appreciated by our customers for their long life & durability. We supply our most popular product Stainless Steel 317 Forged Socket Weld Elbow Fittings to our customers worldwide in specific time. This elbow is non-magnetic in the annealed condition but may become slightly magnetic as a result of welding.

our offered Alloy 317 Socket Weld Caps are comprehensively used as a piece of compound and petrochemical organizations, these are produced using high survey tough steel as the crude material to ensure tip top and whole deal usage. Our range of UNS S31700 Socket Weld Tees/Lateral Tees are very suitable for use in very high, as well as in low temperature. we also get huge demand for our superior quality SS 317 Socket Weld Crosses that are used in application across diverse industries, as well, owing to their compliance to industry defined standards.