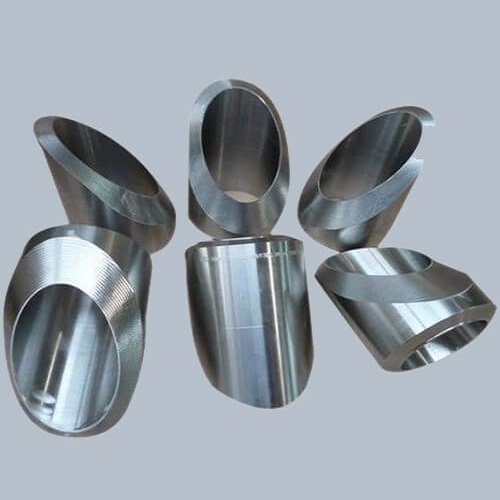

With thorough knowledge of variegated aspects of the market, we DUPLEX STEEL & ENGINEERING are specialize in manufacturing & exporting of top-notch quality Stainless Steel 904L Socket Weld Fittings. Our SS 904L Socket Weld Fittings are designed and developed in accordance with industrial quality standards. Our offered SS 904L Socket welding Cap Fitting has key features such as Sturdiness, Longer service life, Easy to use, Sturdy construction, Rust resistance etc. and highly demanded by automotive & houshold application.

The alloy 904L Socket Weld Union Fittings contains copper which gives it the corrosion resistance tendency to the conventional chrome, specially to phosphoric acid, acetic acid and sulphuric acid. Our Stainless Steel 904L Forged Socket Weld Elbow Fittings is resistance to pitting in chloride solutions and to both crevice and stress corrosion cracking. Tjese are also non magnetic in all the environments and has distinguished formability and weldability.